Nitrogen-free syngas production

In an energy transition context, the combination of pyrogasification and biomethanation processes is an interesting option for biomethane production at small or medium scale. Pyrogasification allows the transformation of lignocellulosic biomass into syngas composed mainly of H2, CO, CO2 and CH4. This syngas is then converted into biomethane via the biological methanation process. This research work is focused on biomass pyrogasification and the production of nitrogen-free syngas suitable for biological methanation. The produced syngas should not contain N2.Actions

PhD work of Sévrin TCHNI TANOH

In collaboration with Terrawatt companies, France

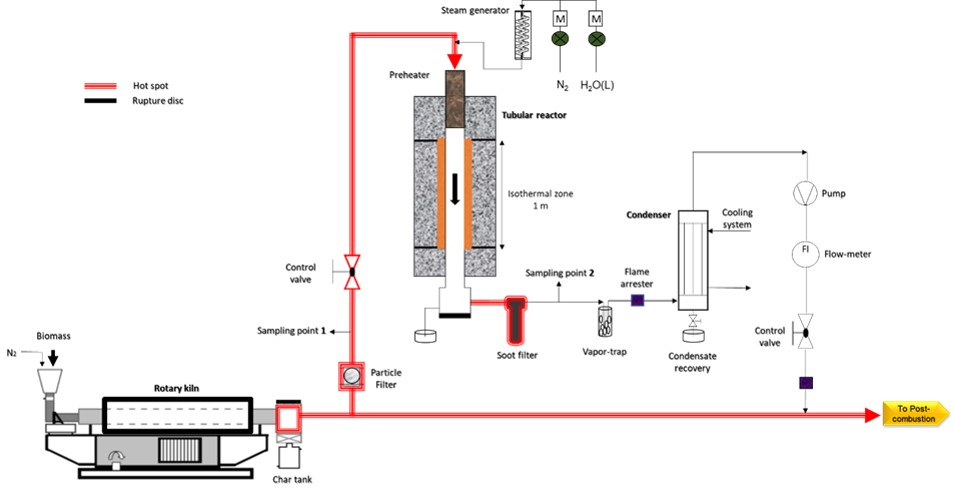

Abstract: A new pyrogasification process on a pilot scale was developed at RAPSODEE center of IMT Mines Albi. It consists of a rotary kiln and a tubular reactor, both indirectly heated and connected in series. The newly adopted approach performs the biomass pyrolysis in the rotary kiln at 800°C and transfers the volatile matters to the tubular reactor to undergo non catalytic cracking and reforming reactions. The volatile matters conversion efficiency was evaluated at different cracking and reforming temperatures and for different gas residence times. The effect of steam addition was also evaluated. Green waste and wood were the selected feedstocks. A nitrogen-free syngas containing more than 50 vol.% of H2 and more than 35 vol.% of CO, and a tar concentration lower than 0.2 g/Nm3 was produced. However, soot formation was identified as the main obstacle in the process. Experimental studies have been carried out to improve the understanding of soot formation and to identify strategies for its reduction. It also allowed the validation of a 1D model based on detailed chemistry. To corroborate this, the combination of pyrogasification and biomethanation processes was modelled in order to propose the energy integration and to quantify overall efficiency of biomass to methane conversion.

PhD work of Manon MATHIEU

Abstract: In this work, various reacting atmospheres different from air will be tested at the pilot scale in a dowdraft fixed bed gasification process. Oxygen will be mixed with CO2 or H20. Theoretical calculations at thermochemical equilibrium were established to serve as first estimates of the impact of reacting atmosphre changes on the performances of the gasifier and on the composition of the produced syngas.

Flowsheet of the coupled "rotary kiln - entrained flow reactor" process operated at pilot scale

General view of the pilot scale (100 kWth) downdraft gasifier

Publications

Green waste pellets pyrolysis in a pilot-scale rotary kiln: effect of temperature on product distribution and characteristics

T.S. TANOH, A. AIT OUMEZIANE, J. LEMONON, F.J. ESCUDERO SANZ , S. SALVADOR

Energy Fuels 2020, 34, 3, 3336-3345, https://doi.org/10.1021/acs.energyfuels.9b04365.

A novel two-stage gasification strategy for nitrogen-free syngas production- pilot-scale experiments

Tchini Séverin Tanoh, Amina Ait Oumeziane, Jérôme Lemonon, Francisco Javier Escudero Sanz, Sylvain Salvador.

Fuel Processing Technology, Elsevier, 2021, 217, pp.106821. ?10.1016/j.fuproc.2021.106821?

Congress

Syngas production from green waste using the combination of a rotary kiln with a tubular reactor.

T. S. TANOH, A. AIT OUMEZIANE, J. LEMONON, F. J. ESCUDERO SANZ, S.SALVADOR

WasteEng 2020, July 13-16, 2020, Guelph, Canada